2024 SPECIAL COMMENDATION – SHADE SAILS OR STRUCTURES – COMMERCIAL

OUR AWARDS

2024 AWARD WINNER FOR CUSTOM PROJECTS

2024 AWARD WINNER FOR TENSION STRUCTURES

The Noosa Council have updated the Sunshine Beach skate park, the park still has the vert ramp but

For this award-winning project, we needed to create two custom shade sails with curved steelwork and asymmetrical elements

It was challenging for our client to find an outdoor awnings supplier in Brisbane who could give them

Increasing functionality, ensuring adequate natural lighting, and maintaining a sleek, elegant appearance was our challenge for this stunning

Our client, Phil needed a multi-solution: firstly, waterproof shade protection for his pool and deck, privacy from neighbouring

Our client’s East facing apartment needed cover from the sun, rain and when entertaining guests. Being a rooftop

Client Australia Zoo Timeframe to complete shade structure 15 Days Location of shade structure Beerwah in Queensland Shade

In the 1980s, Noosa Council repurposed an extra-large bird aviary at Noosa Botanic Gardens to a shade house

The existing shade sails and approximately 60 percent of the steelwork had major design and specification flaws leading

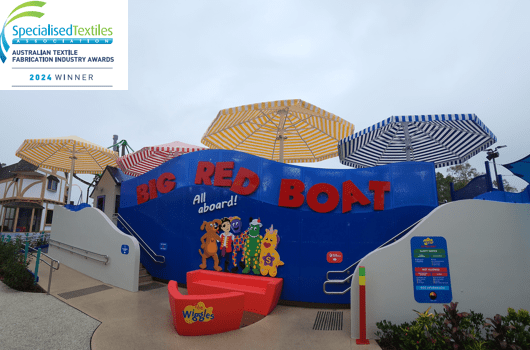

The client required an outdoor blind solution to fix existing umbrellas. Corporate branding was required on the new

The client requested a rooftop shade solution over a children’s sandpit that was retractable and minimised loads into