Custom Shade Sails Brisbane

YOU ARE HERE:

Commercial Shade sails, or sun sails, are minimal maintenance solutions that are cost-effective for providing shade and UVR protection to any outdoor area. For this reason, shade sails are ideal for playgrounds, council parks, childcare centres, commercial applications, domestic applications, and sporting clubs. Shade sails in Brisbane provide stylish and effective sun protection for your outdoor spaces, and Versatile Structures offers a wide range of options to suit any need.

Types of shade sails

Shade structures should be considered as an investment and asset as they transform a property and increase its value. With many diverse types of shade sails solutions to choose from, it is ideal to engage a specialist and ensure the solution you are after will not only meet your functional and aesthetical requirements, but also offer sufficient cover and protection.

Here is an overview of high-quality shade sails, that can be made from waterproof (PVC) or fabric.

Waterproof shade sails can be water resistant and offer protection only from light rain, or completely waterproof or leak-proof, even in torrential downpours. They are lower maintenance solutions, as most waterproof shade sails are self-cleaning, using the rainwater to clean themselves. Waterproof shade sails are also effective at blocking out the harsh UV rays of the sun.

Retractable shade sails are flexible shade solutions that can open or close manually or electronically as needed, to keep outdoor areas comfortable all year round. Domestically they are perfect for alfresco areas, while commercially cafés and restaurants can extend their footprint with this solution.

Shade sails can block out up to 99% of harmful UVR rays from the sun, providing they are of a quality grade. Shade sails are manufactured from high-density polyethylene with UV additives that either reflect or absorb UV rays, while lower-quality shade cloths from hardware stores offer lesser UVR protection. Also, lower quality shade cloths do not as long as shade cloths with monofilament weave, which is a quality feature to look out for.

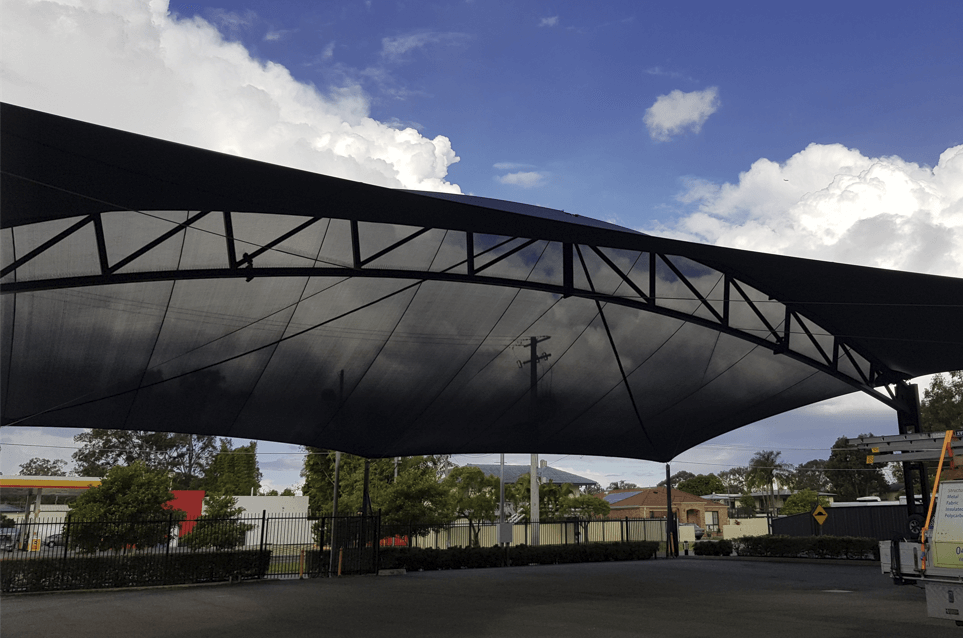

Fixed shade sails can span large distances without support structures and are ideal for commercial car park shading as well as other custom commercial requirements like covering swimming pools or grandstands. Our commercial shade sails are built to last and withstand the harsh Australian climate.

Custom shade sailsrequire a site inspection and are designed by a draftsman who considers the location, overall shape, and 3D geometry while the install team ensures the install posts are secure and every measurement is accurate to the nearest millimetre. Custom shade sails have grown in popularity in Brisbane as property owners have seen the value in having a sturdy and dependable shade sail. We believe Brisbane specifically has grown as it deals with some extreme weather from really hot, high winds as well as high rainfall. Read more about our custom domestic shade solutions.

The lifespan of shade sails

The lifespan of waterproof shade sails, like any other shade structure, can vary depending on several factors. A good quality shade sail structure and regular maintenance program which includes visual inspections and annual re-tensioning will add to the maximum lifespan of your investment. Quality shade sails in Brisbane can have a lifespan of up to 30 years and come with up to a 15-year warranty, even in harsh weather conditions experienced in Brisbane, Gold Coast, and Sunshine Coast.

Thanks to the advancements in fabric manufacturing, our fabric structures are custom-built using high spec International, European, and Australian materials that offer long-lasting durability and performance. All Versatile Structures shade sails and shade solutions are engineered and designed with a long life in mind. We use only the finest quality architectural fabric materials with exceptionally durable steel at their core.

Fire performance

Other than considering how much protection you want from UV radiation another important consideration for the shade fabric you choose is how resistant the shade cloth is to fire. Older shade cloth hasn’t had the best reputation for being a great fire retardant. All Versatile Structures’ shade cloths are tested to AS1530 Parts 2 &3 use a fixed flame in contact with the fabric and measure radiant heat near a fabric to determine its flammability, ignition, spread of flame, and smoke-developed index ranges. To read more about fire performance here.

Key benefits of our Shade Sails

- Cost-effective options from $5,000

- Engineered to specific site conditions

- Custom fabricated to exact design specifications

- Steel coatings to suit site-specific conditions

- Highest quality materials and products used

- 10-to-15-year warranty

Time frame

As with any building project, there are factors like weather and council approval that can impact the timeframes of a project. All things considered, the average shade structure project takes around 12 weeks to complete. For a full breakdown of how the 12 weeks is made up read our article “How much time to allow for a custom shade project“

Australian made

Our Shade sails are proudly Australian-made in Brisbane. We use the best materials possible to ensure durability. For tailored solutions, Versatile Structures specializes in custom shade sails in Brisbane, designed to fit your specific requirements perfectly.

Licensee ID number: 15969

Shade sail repairs

A properly installed shade structure with quality shade fabric should last for a number of years without needing to be adjusted however as we all know the weather in Brisbane and the surrounding areas like Gold Coast and Sunshine Coast can see some pretty high winds. The highest recorded gust is 263km/h in Queensland. If your shade structure is in need of retention or fixing a tear there are a couple of options available. Learn more about what to do about shade sail damage here

Recommended shade structure applications

- Domestic

- Parks

- Playgrounds

- Landscaping

- Schools

- Childcare Centres

- Car parks

Shade Sail Fabrics and Colours

Shade structure colours

Versatile Structures Shade Sail Solutions

Versatile Structures has an excellent reputation for creating high-quality and long-lasting custom domestic and commercial shade sails, fit for Brisbane, Gold Coast, and Sunshine Coast’s harshest weather conditions.

Our team’s experience working within this region and award-winning shade sail designs will ensure you receive the most effective and structurally sound shade sail Brisbane solutions possible. With our sail shade in Brisbane expertise, we can create any shape imaginable and ensure you will enjoy your custom shade sail structure long into the future.

Shade Sail Articles

- The Importance of Shade Structures in Enhancing Public Spaces

- The Benefits of Shade Structures for Shopping Centres

- Your One-Stop Shop for Custom Fabric Structures

- Looking for a Brisbane shade structure solution?

- What Architects consider when designing shade structures

- Looking for the Best Shade Sails Under the Sun

- Customising Industrial Shades for Your Needs

- The psychology of choosing a shade sail colour

- Shade structures and sustainability Shade structures and sustainability

- Using high-quality shade structure hardware is key

- Top five shade sail fabrics and how to get the perfect cover

- The best shade sails under the sun

- A Guide to shade structure styles

- When to install heavy-duty shade sails

- Repair or replace your sail shade in Brisbane?

- Shade structures – your questions answered

- What’s the difference between shade sails and shade structures?

- Five top tips to identify a quality shade structure

- What to look for in a reputable shade structure operator

Custom shade sails in Brisbane offer several benefits compared to off-the-shelf or standard shade sail options.

In summary, custom shade Brisbane sails offer the advantage of tailored design, precise fit, and enhanced aesthetics, making them a versatile and functional shading solution for a wide range of applications, from residential properties to commercial spaces.

Frequently Ask Questions

Commercial shade sails can be made from various materials, and their fire resistance depends on the specific fabric or material used. Shade sails are typically constructed using fabrics that are designed to be flame-resistant or fire-retardant to varying degrees. Here are some common materials and considerations regarding the fire resistance of commercial shade sails:

Fire-Resistant Fabrics: Many shade sails are made from fire-resistant fabrics that have been treated with fire-resistant coatings or additives. These treatments are designed to inhibit the spread of flames and reduce the risk of the fabric catching fire. Fire-resistant fabrics are often used in commercial applications where fire safety is a concern.

Materials Certification: When purchasing commercial shade sails, it’s essential to inquire about the fabric’s fire resistance certification. Reputable manufacturers should provide information about the fabric’s compliance with relevant fire safety standards, such as NFPA 701 in the United States or other local regulations.

Maintenance: It’s crucial to maintain shade sails properly to preserve their fire resistance. Over time, exposure to environmental factors like UV radiation and moisture can degrade the fire-resistant properties of the fabric. Regular cleaning and maintenance can help ensure that the shade sails continue to meet fire safety standards.

Local Regulations: Fire safety regulations can vary by location, so it’s important to consult with local authorities or building code officials to ensure that your commercial shade sails comply with any specific fire safety requirements in your area.

Customisation: Some shade sail manufacturers offer customisation options, allowing you to choose fabrics with specific fire resistance properties that meet your project’s needs and local regulations.

When selecting commercial shade sails, it’s essential to work with reputable suppliers and manufacturers who can provide documentation regarding the fire resistance of the materials used.

Custom shade sails offer several benefits compared to off-the-shelf or standard shade sail options. These custom-designed and tailored shade structures are uniquely created to meet specific needs and preferences. Here are some of the key benefits of custom shade sails:

Precise Fit: Custom shade sails are designed to fit your space perfectly, whether it’s a residential backyard, commercial courtyard, or other outdoor area. This ensures optimal coverage and aesthetics.

Design Flexibility: Custom shade sails allow you to choose the shape, size, and layout that best suits your space and design vision. This flexibility enables you to create a unique and visually appealing shading solution.

Aesthetic Appeal: You have greater control over the aesthetics of custom shade sails, including the choice of fabric colours, patterns, and hardware finishes. This allows you to match or complement your existing architectural and landscaping elements.

Enhanced Sun Protection: Custom shade sails can be strategically designed to provide maximum sun protection in specific areas, helping to create cooler and more comfortable outdoor environments.

Personalisation: Custom shade sails can be personalised with logos, branding, or artwork, making them an effective marketing tool for businesses or a way to add a personal touch to residential spaces.

Improved Functionality: By tailoring the design to your needs, custom shade sails can offer better functionality, whether it’s shading a seating area, playground, pool, or parking lot.

Optimised Shade Coverage: Custom shade sail designs can take into account the sun’s position throughout the day and the changing seasons, ensuring that the shaded area remains effective in providing relief from the sun.

Integration with Existing Structures: Custom shade sails can be designed to integrate seamlessly with existing architectural elements or structures, enhancing the overall aesthetics of your property.

Enhanced Durability: Custom shade sails can be constructed with high-quality materials and hardware to ensure durability and longevity, even in challenging weather conditions.

Increased Property Value: Well-designed and aesthetically pleasing custom shade sails can add value to residential or commercial properties, improving their attractiveness to potential buyers or tenants.

Tailored Budget: Custom shade sails can be designed to meet your budget constraints while still achieving your shading and design goals. You have more control over the materials and features that are included.

Environmental Considerations: Custom shade sails can be designed with eco-friendly materials and features, aligning with sustainability goals and reducing environmental impact.

In summary, custom shade sails offer the advantage of tailored design, precise fit, and enhanced aesthetics, making them a versatile and functional shading solution for a wide range of applications, from residential properties to commercial spaces. For those in Brisbane, sail shades provide an ideal solution to protect against the harsh sun while enhancing the visual appeal of any outdoor area.

In Brisbane, Australia, as in many other locations, the need for approval or permits for a shade sail installation depends on various factors, including the size, location, and type of shade sail you plan to install. The regulations and requirements can vary by local government, so it’s essential to check with the Brisbane City Council or the local government authority in your specific area to get accurate and up-to-date information.

Shade sails are primarily designed to provide shade and protection from the sun’s harmful ultraviolet (UV) rays. While they can offer some limited protection from light rain and drizzle, they are not intended to be fully waterproof and are not a substitute for proper rain protection.

The lifespan of waterproof shade sails, like any other shade structure, can vary depending on several factors. The quality of materials, the level of maintenance, and environmental conditions all play a role in determining how long a waterproof shade sail will last.

In general, well-maintained waterproof shade sails can last anywhere from 5 to 15 years or more. High-quality materials and proper care can significantly extend their lifespan. However, it’s essential to follow the manufacturer’s guidelines for maintenance and consider the specific environmental conditions and usage of the shade sail when estimating its expected lifespan.